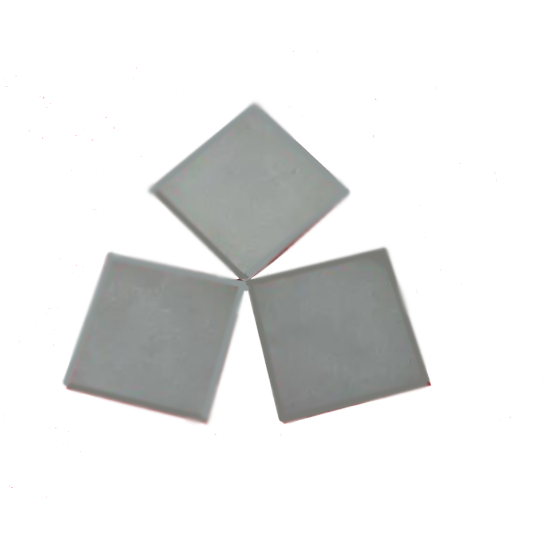

Silicon nitride ceramic substrates (Si3N4)

Silicon nitride [Si3N4] is a ceramic, the features of which are its increased strength characteristics and increased wear resistance, relative to other types of ceramic materials. Therefore, it is best used in structures where high strength of the product and its resistance to high temperature changes are necessary.

Due to their mechanical characteristics, products made using silicon nitride perfectly withstand conditions of prolonged thermal cycling, shocks, tests with increased friction, as well as interaction with aggressive media.

Specifications

|

Properties |

Material |

|

|

Si3N4 |

||

|

Colour |

Gray |

|

|

Bulk density |

г/см3 |

≥ 3,20 |

|

Surface roughness Ra (grinding) |

мкм |

— |

|

Roughness of the polished surface (Ra) |

мкм |

Ra 0,05 |

|

Mechanical properties |

||

|

Flexural strength |

МПа |

900 |

|

Compressive strength |

МПа |

2500 |

|

Elastic modulus |

ГПа |

315 |

|

Vickers Hardness |

ГПа |

|

|

Fracture toughness |

|

7,5 |

|

Physical properties |

||

|

Coefficient of thermal expansion (25-1000°C) |

10 -6 /°C |

3,1 |

|

Thermal conductivity (25°C) |

Вт/м∙°K |

19 |

|

Specific heat capacity |

Дж/кг*К |

3,1 |

|

Heat shock resistance |

С |

800 |

|

Maximum operating temperature |

С |

1400 |

|

Dielectric strength |

|

15 |

|

Volumetric resistance (25 С) |

|

≥ 1014 |

|

Dielectric constant (1 МГц) |

- |

9,0 - 10,0 |

|

Dielectric losses (1МГц, 25°C) |

∙10 -4 |

4 |

|

Technological properties |

||

|

DBC technology |

- |

|

|

Thick-film technology |

- |

|

|

Thin-film technology |

|

|

Application area

The created boards based on ceramics of silicon nitride or carbide are used in the following areas:

- as an insulator;

- manufacturing of storage devices;

- production of integrated circuits;

- a more reliable and durable alternative for aluminum oxide (Al2O3)

- the basis for the manufacture of high-power electronics boards

- substrates for sensors, electronic devices that are operated under the influence of aggressive environments, etc.