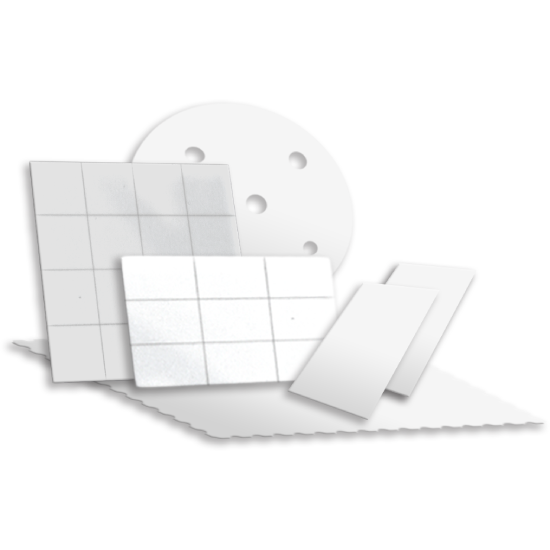

Aluminium oxide ceramic substrates (Al2O3)

Ceramic substrates made of aluminum oxide Al2O3 are the basis for the creation of hybrid integrated circuits, ceramic capacitors, resistors, heaters, various semiconductor elements and electrical products.

The raw material for the production of vacuum-tight ceramics Al2O3 is corundum, so ceramics are often called not only "aluminum oxide", but also corundum ceramics. Vacuum-tight corundum ceramics are resistant to various acids and other aggressive media, and are an excellent durable insulator. Substrates made of Al2O3 do not lose their performance in case of sudden temperature changes.

An important role is played by the percentage of aluminum oxide in the total volume and its crystal lattice. They determine its future performance characteristics, such as thermal conductivity, hardness, bending strength, coefficient of specific expansion and others.

Specifications

|

Properties |

Materials |

|||

|

Al2O3 94,4% (ВК-94ДН) |

Al2O3 96,0% (ВК-96ДН) |

Al2O3 99,6% (ВК-100ДН) |

||

|

Colour |

pink |

white |

white |

|

|

Bulk density |

г/см3 |

3,60 |

3,70 |

3,90 |

|

Surface roughness, Ra

(grinding) |

мкм |

- |

0,2-0,7 |

0,1 |

|

Surface roughness Ra (polished) |

мкм |

- |

≤ 0,03 |

≤ 0,05 |

|

Mechanical properties |

||||

|

Flexural strength |

МПа |

280 |

350 |

500 |

|

Compressive strength |

МПа |

|

|

450 |

|

Elastic modulus |

ГПа |

- |

330 |

330 |

|

Vickers hardness |

ГПа |

- |

14 |

16 |

|

Fracture toughness |

|

- |

- |

-

|

|

Physical properties |

||||

|

Coefficient of thermal expansion (40-300°C) |

10 -6 /°C |

6,5 - 7,5 |

6,5 ~ 7,5 |

6,2 ~ 7,2 |

|

Coefficient of thermal expansion (300-800 С) |

|

|

6,5 ~ 8,0 |

6,5 ~ 8,2 |

|

Thermal conductivity (25°C) |

Вт/м∙°K |

15 - 20 |

≥ 24 |

≥ 30 |

|

Specific heat capacity |

Дж/Кг∙°К |

- |

750 |

750 |

|

Dielectric strength |

|

|

≥ 17 |

≥ 15 |

|

Volumetric resistance(25 С) |

|

|

≥ 1014 |

≥ 1014 |

|

Dielectric constant (1 МГц) |

- |

9,0 - 10,0 |

9 ~ 10 |

10 |

|

Dielectric losses (1МГц, 25°C) |

∙10 -4 |

4 |

2 |

2 |

|

Sizes |

||||

|

Distance between scribing lines, мм |

|

|

1±0,05 |

1±0,05 |

|

Minimum hole diameter, мм |

|

|

0,1±0,05 |

0,1±0,05 |

|

Thickness, мм |

|

|

0,2 ~ 2,0 |

≤ 0,635 |

|

Thickness tolerance (min), мм |

|

|

± 0,03 |

± 0,04 |

|

Dimensions (max), мм |

|

|

139,7 x 190,5 |

120 x 120 |

|

Dimensional tolerance (min), мм |

|

|

(+0,15 / -0,05) |

±0,1; ±2 |

|

Metallisation |

||||

|

DBC technology |

+ |

+ |

- |

|

|

Thick-film technology |

+ |

+ |

+ |

|

|

Thin-film technology |

+ |

+ |

+ |

|

Application area

- power electronics, converter equipment (radio communication devices, broadcasting equipment, medical electrical equipment, etc.);

- insulation gaskets for heat removal from electronic components to the cooling radiator;

- protectors for elements of piezoelectric converters;

- auto electronics (multiplicated boards for resistors, rheostats, fuel level sensors, pressure sensors, LED headlights, electric power steering, ABS, ASR systems, etc.)

- precision substrates for microwave GIS and microassemblies with a high density of holes and recesses for crystals;

- carriers of sensor circuits of toxic substances, ionizing radiation, magnetic field, etc.;

- semiconductor industry (thermoelectric modules and heat removal devices, analytical equipment, wireless power sources, energy-efficient waste heat disposal systems, electronical, laser and optical systems, LEDs (energy-saving technologies), IGBT modules