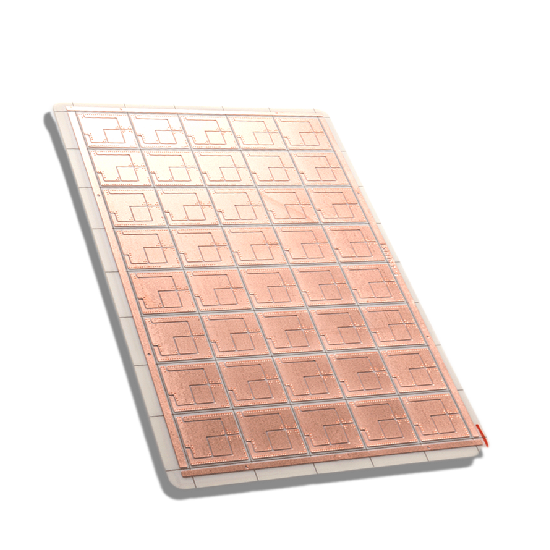

AMB technology (Active Metal Braze)

AMB (Active Metal Braze) is one of the technologies that are used in the world to create boards with thick metallization (from 127 microns).

AMB (Active Metal Braze) is one of the technologies that are used in the world to create boards with thick metallization (from 127 microns).

It is in the AMB technology that a solution has been found to the problem of the mismatch of the KTR of copper with a ceramic substrate, which is key in the case of DBC technology. The coordination of the KTR is achieved due to the formation of a matching layer between the conductive layer of copper and ceramics, which prevents the occurrence of internal stresses under thermal cycling conditions and is also an adhesive sublayer. A finishing coating is applied to the main metallization layer.

The main disadvantage of the technology is the presence of thermal conductivity in the matching layer, which worsens the heat removal from the conductive layer. In this connection, it is recommended to use ceramics based on aluminum nitride, because of its high thermal conductivity.

Also, bubbles may form in the intermediate connection, reducing the heat sink. It is most noticeable when applying a matching layer in the form of a special paste.

Due to the unique properties of the boards obtained by the AMB method, it becomes possible to carry out high-temperature soldering in an H2 environment. The boards have extreme thermal and energy cycle resistance (more than 15,000 power cycles in on/off mode attt=100 ° C and more than 5,000 thermal cycles at ∆t=200 ° C).

Specifications

| Properties | ||||

| The presence of bubbles in the solder joint | < 5% от общей площади соединения (площадь 1 пузыря < 1%) | |||

| Cu thickness*, мкм | от 100 до 800 | |||

| Ceramics | AlN, Al2O3 | |||

| Adhesion, Н/мм2 | > 15 | |||

|

Cu thickness

|

Resolution |

|||

|

Distance between conductors, мм |

Width of conductors, мм |

|||

|

Тип. |

Min |

Тип. |

Min |

|

|

0,127 |

0,30 |

0,25 |

0,30 |

0,25 |

|

0,20 |

0,50 |

0,40 |

0,50 |

0,40 |

|

0,25 |

0,60 |

0,50 |

0,60 |

0,50 |

|

0,30 |

0,70 |

0,50 |

0,70 |

0,50 |

|

0,40 |

0,80 |

0,60 |

0,80 |

0,60 |

Application area

- power integrated circuits;

- other elements of the electronic and microelectronic industry.

- car electronics;

- various high-power semiconductor devices and their packaging;

- medical equipment;

- electric locomotive power engines;

- Microwave devices;